What are Bearings?

Bearings are highly engineered, precision-made components that enable machinery to move at extremely high speeds and carry remarkable loads with ease and efficiency.

Bearings must be able to offer high precision, reliability and durability, as well as the ability to rotate at high speeds with minimal noise and vibration.

Bearings are found in applications ranging from automobiles, airplanes, computers, construction equipment, machine tools, DVD players, refrigerators and ceiling fans.

If something twists, turns or moves, it probably has a bearing in it.

Different Types of Bearings

A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races.

A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races.

The purpose of a ball bearing is to reduce rotational friction and support radial and axial loads. It achieves this by using at least two races to contain the balls and transmit the loads through the balls. In most applications, one race is stationary and the other is attached to the rotating assembly (e.g., a hub or shaft). As one of the bearing races rotates it causes the balls to rotate as well. Because the balls are rolling they have a much lower coefficient of friction than if two flat surfaces were sliding against each other.

A needle roller bearing is a bearing which uses small cylindrical rollers.The difference between a needle roller bearing and roller bearing is the ratio of diameter and length of their rollers, when the ratio of the diameter and the length of roller of a roller bearing is between the interval of 0.1 to 0.4, that roller bearing is called a needle roller bearing. They are used to reduce the friction of a rotating surface.

A needle roller bearing is a bearing which uses small cylindrical rollers.The difference between a needle roller bearing and roller bearing is the ratio of diameter and length of their rollers, when the ratio of the diameter and the length of roller of a roller bearing is between the interval of 0.1 to 0.4, that roller bearing is called a needle roller bearing. They are used to reduce the friction of a rotating surface.

Needle bearings have a large surface area that is in contact with the bearing outer surfaces compared to ball bearings. Additionally there is less added clearance (difference between the diameter of the shaft and the diameter of the bearing) so they are much more compact. The typical structure consists of a needle cage which orients and contains the needle rollers, the needle rollers themselves, and an outer race (sometimes the housing itself).

Radial needle bearings are cylindrical and use rollers parallel to the axis of the shaft. Thrust needle bearings are flat and use a radial pattern of needles.

Full complement bearings have solid inner and outer rings and rib-guided cylindrical rollers. Since these bearings have the largest possible number of rolling elements, they have extremely high radial load carrying capacity and are suitable for particularly compact designs.

Needle bearings are heavily used in automobile components such as rocker arm pivots, pumps, compressors, and transmissions. The drive shaft of a rear-wheel drive vehicle typically has at least eight needle bearings (four in each U joint) and often more if it is particularly long, or operates on steep slopes.

Additional clarification of needle roller: According to “Marks’ Standard Handbook for Mechanical Engineers”, a needle bearing is a roller bearing with rollers whose length are at least four times their diameter.

The inner and outer ring raceways are segments of cones and the rollers are also made with a taper so that the conical surfaces of the raceways and the roller axes if projected, would all meet at a common point on the main axis of the bearing. This geometry makes the motion of the cones remain coaxial, eliminating sliding motion in the bearing.

The inner and outer ring raceways are segments of cones and the rollers are also made with a taper so that the conical surfaces of the raceways and the roller axes if projected, would all meet at a common point on the main axis of the bearing. This geometry makes the motion of the cones remain coaxial, eliminating sliding motion in the bearing.

This conical geometry is used as it gives a larger contact patch, which permits greater loads to be carried than with spherical (ball) bearings, while the geometry means that the tangential speeds of the surfaces of each of the rollers are the same as their raceways along the whole length of the contact patch and no differential scrubbing occurs. When a roller slides rather than rolls, it can generate wear at the roller-to-race interface, i.e. the differences in surface speeds creates a scrubbing action. Wear will degenerate the close tolerances normally held in the bearing and can lead to other problems. Much closer to pure rolling can be achieved in a tapered roller bearing and this avoids rapid wear.

The rollers are guided by a flange on the inner ring. This stops the rollers from sliding out at high speed due to their momentum.

The larger the half angles of these cones the larger the axial force that the bearing can sustain.

Tapered roller bearings are separable and have the following components: outer ring, inner ring, and roller assembly (containing the rollers and a cage). The non-separable inner ring and roller assembly is called the cone, and the outer ring is called the cup. Internal clearance is established during mounting by the axial position of the cone relative to the cup.

Metric tapered roller bearings follow the designation system defined by ISO 355.

Rollers used in spherical roller bearings are thicker in the middle and narrow at the ends, and its race is shaped to match. They can adjust to support misaligned loads.

Rollers used in spherical roller bearings are thicker in the middle and narrow at the ends, and its race is shaped to match. They can adjust to support misaligned loads.

The construction of spherical rollers are complex and difficult to produce so they are expensive. Apart from that these bearings have higher friction compared to ball bearing because different parts of the spherical rollers run at different speeds on the rounded race. Thus there are opposing forces along the bearing/race contact increasing the friction.

Spherical bearings are used in numerous applications where rotational motion changes the alignment of its axis of rotation. One of its important example is a tie rod on a vehicle suspension. Other important uses of spherical bearings have been in car suspensions, trackballs, computer mouse, heavy machinery, sewing machines, drive shafts, etc.

Thrust bearings are a particular type of rotary bearing that allow rotation between parts used but they are designed to support axial loads like vertical shafts for which spherical, conical or cylindrical rollers are used. They are used in gearsets like in car transmissions between gears and between the housing and the rotating shafts.

Thrust bearings are a particular type of rotary bearing that allow rotation between parts used but they are designed to support axial loads like vertical shafts for which spherical, conical or cylindrical rollers are used. They are used in gearsets like in car transmissions between gears and between the housing and the rotating shafts.

Thrust bearings are of different varieties. Ball thrust bearings are composed of ball bearings supported in a ring. They are used in low thrust applications where the radial load is very small. Thurst roller bearings are made of small tapered rollers arranged so that their axes converge at a point on the axis of the bearing.

Thrust ball bearings, composed of ball bearings supported in a ring, can be used in low thrust applications where there is little axial load.

Cylindrical thrust roller bearings consist of small cylindrical rollers arranged flat with their axes pointing to the axis of the bearing. They give very good carrying capacity and are cheap, but tend to wear due to the differences in radial speed and friction which is higher than with ball bearings.

What someone would normally think of as a bearing, with two concentric metal circles separated by little metal balls. These simple bearings can be found in everything from skateboards to drills.

What someone would normally think of as a bearing, with two concentric metal circles separated by little metal balls. These simple bearings can be found in everything from skateboards to drills.

The purpose of a ball bearing is to reduce rotational friction and support radial and axial loads. It achieves this by using at least two races to contain the balls and transmit the loads through the balls. In most applications, one race is stationary and the other is attached to the rotating assembly (e.g., a hub or shaft). As one of the bearing races rotates it causes the balls to rotate as well. Because the balls are rolling they have a much lower coefficient of friction than if two flat surfaces were sliding against each other.

Ball bearings tend to have lower load capacity for their size than other kinds of rolling-element bearings due to the smaller contact area between the balls and races. However, they can tolerate some misalignment of the inner and outer races.

These bearings are a radial load bearing encased in a housing that can be attached to a surface parallel to the axis of rotation.

These bearings are a radial load bearing encased in a housing that can be attached to a surface parallel to the axis of rotation.

A pillow block, also known as a plummer block or bearing housing, is a pedestal used to provide support for a rotating shaft with the help of compatible bearings & various accessories. Housing material for a pillow block is typically made of cast iron or cast steel.

Pillow blocks usually refer to housings which have a bearing fitted into them and thus the user need not purchase the bearings separately. Pillow blocks are usually mounted in cleaner environments and generally are meant for lesser loads of general industry. These differ from “plummer blocks” which are bearing housings supplied without any bearings and are usually meant for higher load ratings and corrosive industrial environments. However the terms pillow block and plummer block are used interchangeably in certain parts of the world.

A radial load bearing with a threaded rod attached to it. Generally meant to ride on a cam to cause linear motion, these could have other interesting applications.

A radial load bearing with a threaded rod attached to it. Generally meant to ride on a cam to cause linear motion, these could have other interesting applications.

Instead of an inner ring, cam followers have a solid stud (pin) that is threaded so that the cam follower can be quickly and easily attached to appropriate machine components by means of a hexagonal nut.

The Cam Follower is a compact bearing with a high-rigidity shaft and a built-in needle bearing. Most suitable as a guide roller for cam mechanisms and linear motion of automated machines and dedicated machines.

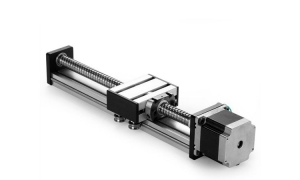

This type of bearing is used extensively to allow for the smooth motion of 3D printer and CNC router heads. Their purpose, unlike the other bearings here, is to restrict radial motion, while allowing smooth linear motion.

This type of bearing is used extensively to allow for the smooth motion of 3D printer and CNC router heads. Their purpose, unlike the other bearings here, is to restrict radial motion, while allowing smooth linear motion.

The linear ball bearing (also called ball bushing or shaft guiding) consists of a polymeric cage with raceway segments made of hardened steel to guide the ball sets within the complete system. Recirculating balls provide unlimited stroke at low friction movement.

Linear Bushing LM is a high precision linear motion rolling guide which travels along a shaft to achieve endless linear motion. In the external cylinder, a retainer, steel balls, etc. are compactly incorporated. Wide variations in size are available for selections suitable for each application.

A linear-motion bearing or linear slide is a bearing designed to provide free motion in one direction. There are many different types of linear motion bearings.

A linear-motion bearing or linear slide is a bearing designed to provide free motion in one direction. There are many different types of linear motion bearings.

Motorized linear slides such as machine slides, XY tables, roller tables and some dovetail slides are bearings moved by drive mechanisms. Not all linear slides are motorized, and non-motorized dovetail slides, ball bearing slides and roller slides provide low-friction linear movement for equipment powered by inertia or by hand. All linear slides provide linear motion based on bearings, whether they are ball bearings, dovetail bearings, linear roller bearings, magnetic or fluid bearings. XY Tables, linear stages, machine slides and other advanced slides use linear motion bearings to provide movement along both X and Y multiple axis.

A rod end bearing, also known as a heim joint (N. America) or rose joint (U.K. and elsewhere), is a mechanical articulating joint. Such joints are used on the ends of control rods, steering links, tie rods, or anywhere a precision articulating joint is required, and where a clevis end (which requires perfect 90 degree alignment between the attached shaft and the second component) is unsuitable. A ball swivel with an opening through which a bolt or other attaching hardware may pass is pressed into a circular casing with a threaded shaft attached. The threaded portion may be either male or female. The heim joint’s advantage is that the ball insert permits the rod or bolt passing through it to be misaligned to a limited degree (an angle other than 90 degrees). A link terminated in two heim joints permits misalignment of their attached shafts (viz., other than 180 degrees) when used in tension. When used in compression, the through-rods are forced to the extreme ends of their ball’s misalignment range, which cocks the link at an oblique angle.

A rod end bearing, also known as a heim joint (N. America) or rose joint (U.K. and elsewhere), is a mechanical articulating joint. Such joints are used on the ends of control rods, steering links, tie rods, or anywhere a precision articulating joint is required, and where a clevis end (which requires perfect 90 degree alignment between the attached shaft and the second component) is unsuitable. A ball swivel with an opening through which a bolt or other attaching hardware may pass is pressed into a circular casing with a threaded shaft attached. The threaded portion may be either male or female. The heim joint’s advantage is that the ball insert permits the rod or bolt passing through it to be misaligned to a limited degree (an angle other than 90 degrees). A link terminated in two heim joints permits misalignment of their attached shafts (viz., other than 180 degrees) when used in tension. When used in compression, the through-rods are forced to the extreme ends of their ball’s misalignment range, which cocks the link at an oblique angle. A Needle Roller Bearing is a bearing which uses small cylindrical rollers.The difference between a needle roller bearing and roller bearing is the ratio of diameter and length of their rollers, when the ratio of the diameter and the length of roller of a roller bearing is between the interval of 0.1 to 0.4, that roller bearing is called a needle roller bearing. They are used to reduce the friction of a rotating surface.

A Needle Roller Bearing is a bearing which uses small cylindrical rollers.The difference between a needle roller bearing and roller bearing is the ratio of diameter and length of their rollers, when the ratio of the diameter and the length of roller of a roller bearing is between the interval of 0.1 to 0.4, that roller bearing is called a needle roller bearing. They are used to reduce the friction of a rotating surface.

Needle bearings have a large surface area that is in contact with the bearing outer surfaces compared to ball bearings. Additionally there is less added clearance (difference between the diameter of the shaft and the diameter of the bearing) so they are much more compact. The typical structure consists of a needle cage which orients and contains the needle rollers, the needle rollers themselves, and an outer race (sometimes the housing itself).

Radial needle bearings are cylindrical and use rollers parallel to the axis of the shaft. Thrust needle bearings are flat and use a radial pattern of needles.

Full complement bearings have solid inner and outer rings and rib-guided cylindrical rollers. Since these bearings have the largest possible number of rolling elements, they have extremely high radial load carrying capacity and are suitable for particularly compact designs.

Needle bearings are heavily used in automobile components such as rocker arm pivots, pumps, compressors, and transmissions. The drive shaft of a rear-wheel drive vehicle typically has at least eight needle bearings (four in each U joint) and often more if it is particularly long, or operates on steep slopes.

Additional clarification of needle roller: According to “Marks’ Standard Handbook for Mechanical Engineers”, a needle bearing is a roller bearing with rollers whose length are at least four times their diameter.

Steel ball bearings are used to reduce friction in rotating parts of automobiles, motor cycles, computers and machine tools. As such, they are required to have semi-permanent durability.

Steel ball bearings are used to reduce friction in rotating parts of automobiles, motor cycles, computers and machine tools. As such, they are required to have semi-permanent durability.Furthermore, the operating noise must be reduced with bearings used for refrigerators and vacuum cleaners at home, and the highest precision is demanded for VTR and HDD bearings.

We have pride in the high precision of our steel balls, which will continue to satisfy each of our client’s needs.

When maintaining the integrity of the ball finish in a corrosive environment is important, choose from our quality stainless steel balls, which are being manufactured for such applications as bearings, bicycle parts, casters and wheels, etc. Stainless Steel balls that we are manufacturing are in general classified into two representative groups viz., high chrome (martensitic) and high chrome-nickel (austenitic) stainless steels.

An Angular Contact ball Bearing uses axially asymmetric races. An axial load passes in a straight line through the bearing, whereas a radial load takes an oblique path that tends to want to separate the races axially. So the angle of contact on the inner race is the same as that on the outer race.

An Angular Contact ball Bearing uses axially asymmetric races. An axial load passes in a straight line through the bearing, whereas a radial load takes an oblique path that tends to want to separate the races axially. So the angle of contact on the inner race is the same as that on the outer race.

Angular contact ball bearings have raceways in the inner and outer rings that are displaced relative to each other in the direction of the bearing axis. This means that they are designed to accommodate combined loads, i.e. simultaneously acting radial and axial loads.